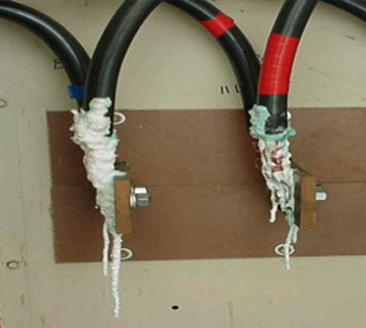

A high voltage PVC/EPDM power cable failed due to plasticizer volatilization.

A customer experienced major quality problems with their HV cables, as evidenced by this photograph. Volatility of the plasticizer was the primary issue, which caused other components of the formulation to exude out. A secondary issue, unrelated to the primary problem, was low extraction resistance to polar and non-polar liquids. This customer came to Hallstar with a time sensitive situation and the need for a new plasticizer.

Using the Paraplex Approach, Hallstar’s proprietary customized plasticizer design system, the customer was supplied with performance data and a sample of the new product, Paraplex® A-8600, within two days. This quick turnaround allowed the customer to speed up the approval of Paraplex® A-8600 within two months.

While Hallstar provided a product that resolved the customer’s primary volatility resistance issues, a secondary issue was their inability to handle the higher viscosity of the new polymeric plasticizer. This issue was quickly resolved by blending the Paraplex® A-8600 with a monomeric plasticizer that was already in the customer’s formulation, thereby reducing viscosity levels. This resulted in a pumpable, easy-to-handle product.

© 2023 Hallstar. All Rights Reserved.